II. Nondestructive Tests

Nondestructive testing methods are used to detect defects that are sub-surface in nature and not detectable in the visual examination. Nondestructive tests are recorded on the appropriate forms to include pertinent inspection data as required.

Magnetic Particle Inspection

In our Magnetic Particle Inspections, we use an electromagnetic yoke which creates a magnetic field for detection of discontinuities parallel to a weld bead.

Electromagnetic Yoke showing position and magnetic field for detection of discontinuities parallel to a weld bead.

Areas Tested:

- Outrigger Jack Box

- Turntable

- Aerial Support Structure

- Platform Support Structure

- Ladder/Boom Stress Areas

For units constructed of ferro-magnetic materials, fillet type welds supporting the main structure are inspected by the magnetic particle methods.

Eddy Current Inspection

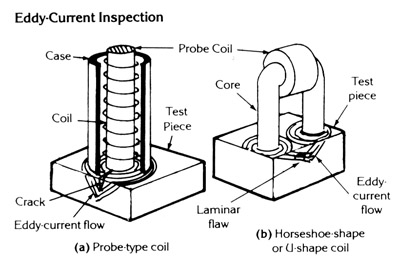

The Eddy Current method of nondestructive testing is used on nonferrous material in order to measure or identify seams, laps, cracks, voids, inclusions, hardness and physical dimensions.

Application of probe-type coils for the detection of cracks and laminar flaws.

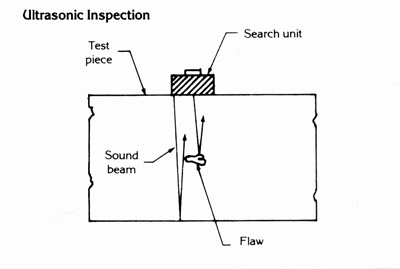

Ultrasonic Inspection

Ultrasonic inspection is used to make evaluations of pins, and physical dimensions for possible internal defects.

Application of the straight-beam (longitudinal wave) contact-type search unit showing reflection technique.