IV. Functional Tests

These tests are performed in order to determine the units ability to operate and maintain its designed structural integrity. Measurements taken at critical areas are compared to the manufacturer's allowable tolerances. All data is documented along with allowable tolerances for quick reference. The ultimate purpose of the data collected is to establish a historical baseline for wear and deterioration. The data will assist in identifying trends that may have an effect on equipment operation.

Functional Tests include:

- Alignment

- Cylinder and Winch Drift

- Level Measurements

- Thickness and Corrosion Measurements

- Timing Test

- Rotation Bearing Tolerances

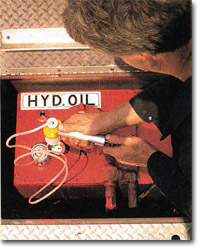

- Hydraulic System Analysis

- Hydraulic Oil Analysis

- Engine Oil Analysis (if Requested)